Haco Q5 CNC PUNCHING MACHINE

Haco Q5 CNC PUNCHING MACHINE : $540,000 - $595,000 AUD ($594,000 - $654,500 Inc. GST)

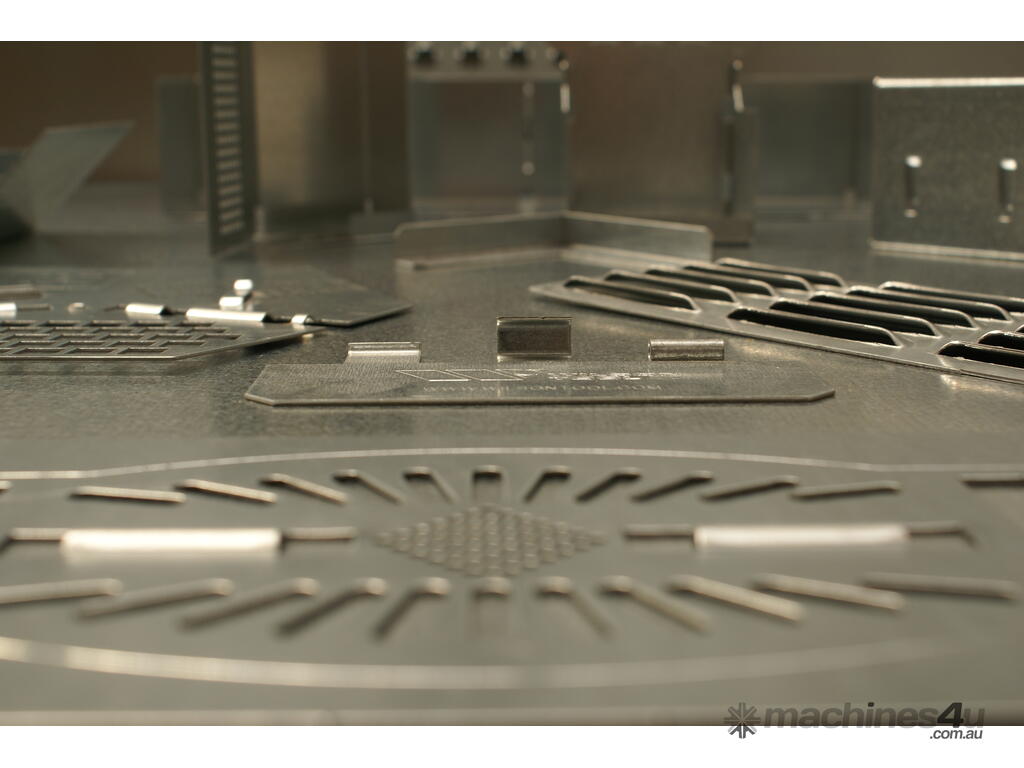

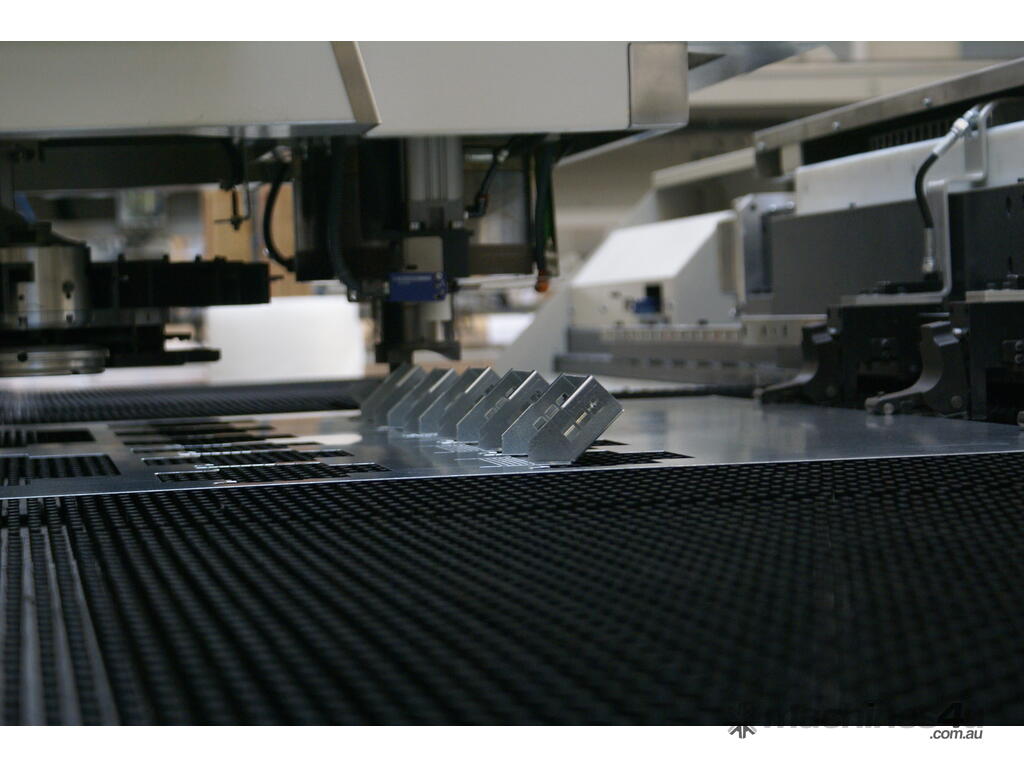

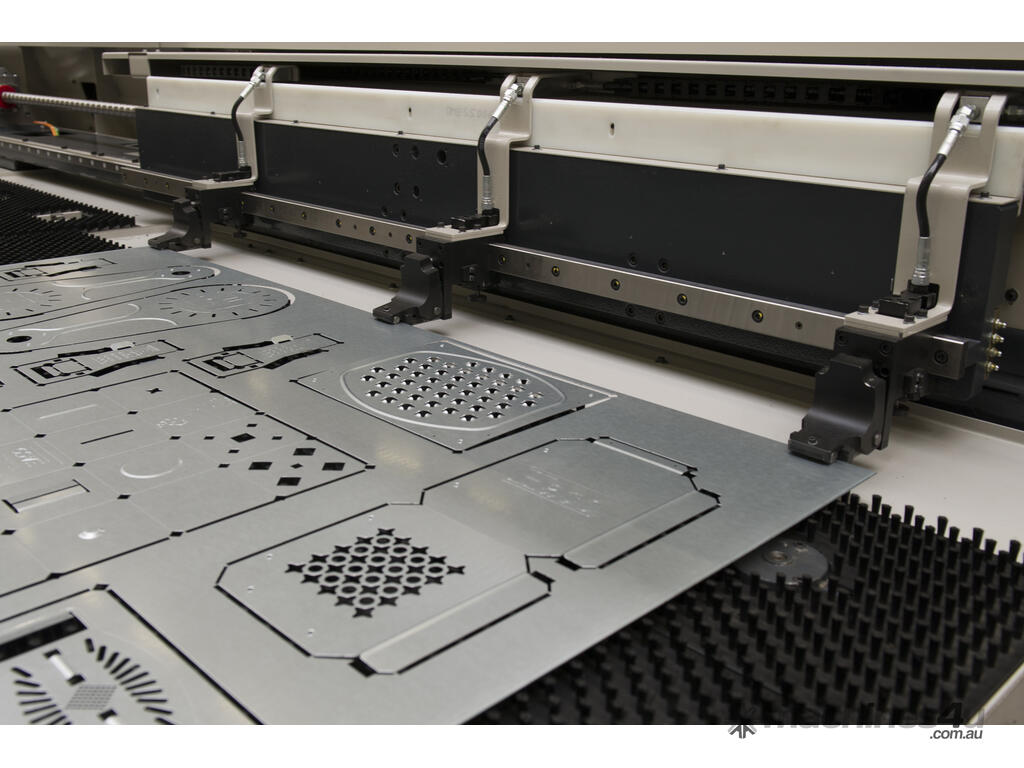

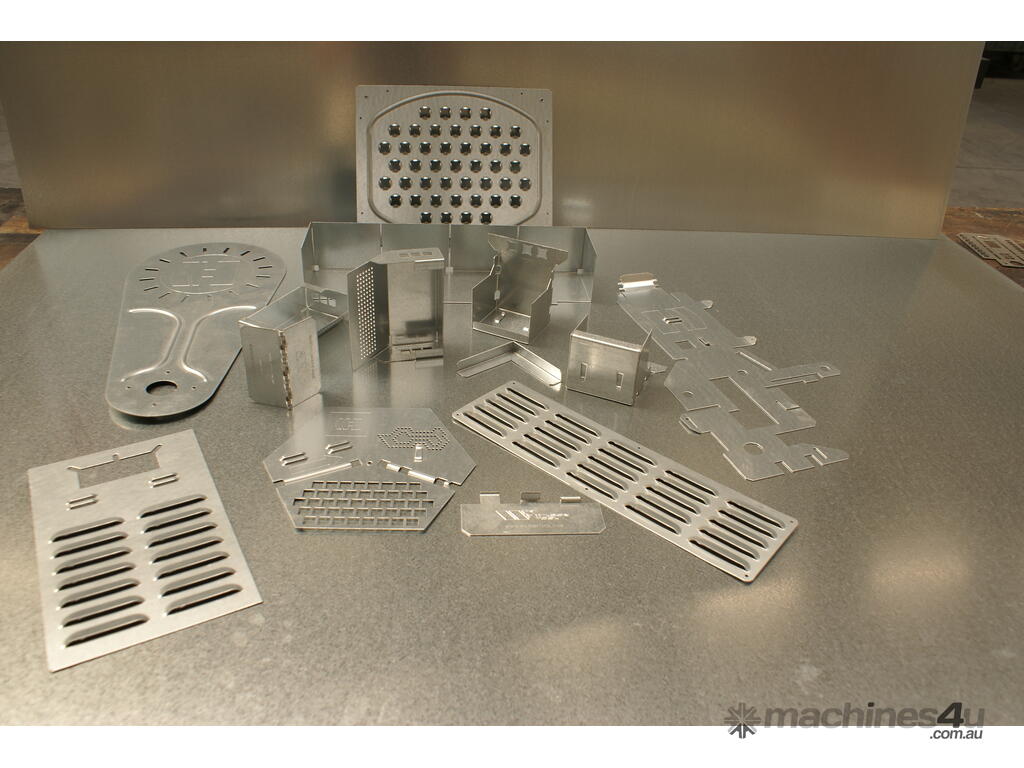

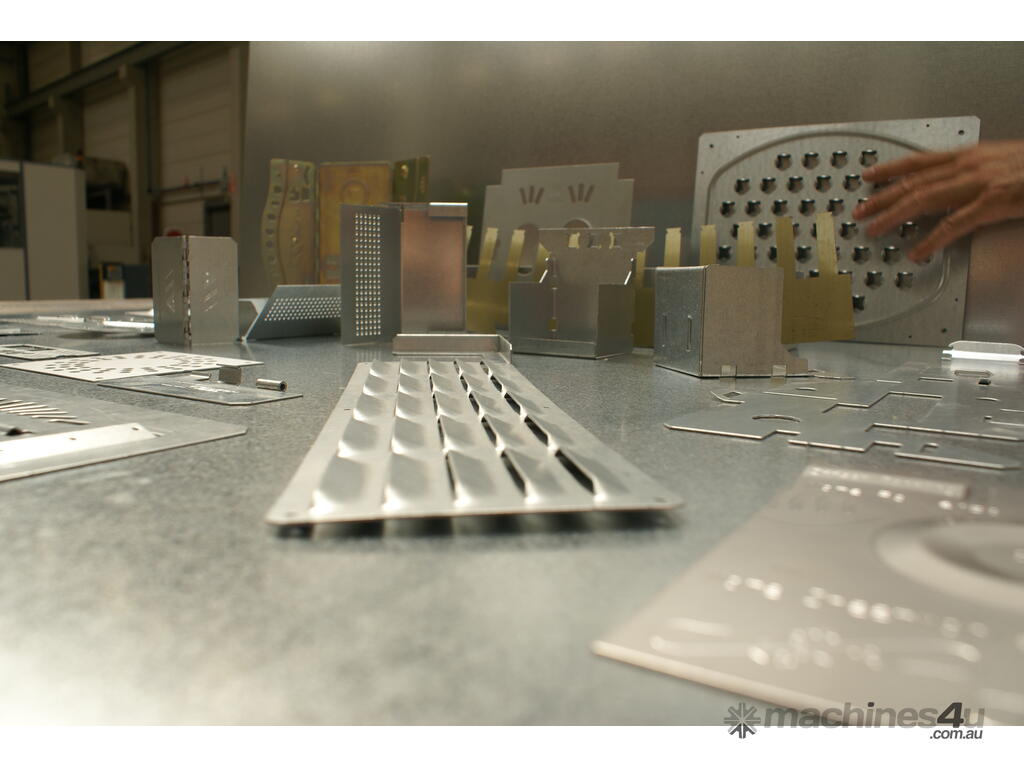

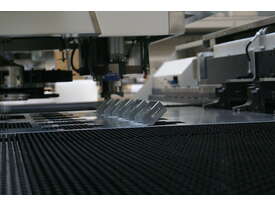

The Haco Series Q5 CNC punching machines convert your workshop into one with the highest productivity and flexibility that can be achieved with a CNC sheet metal machine.

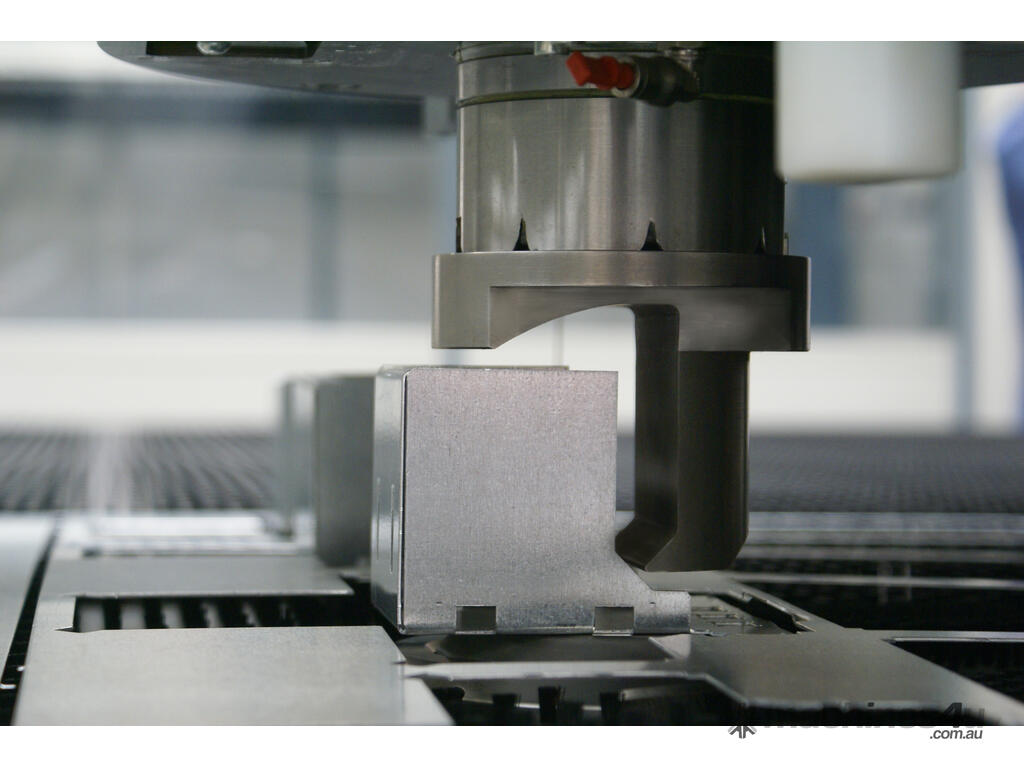

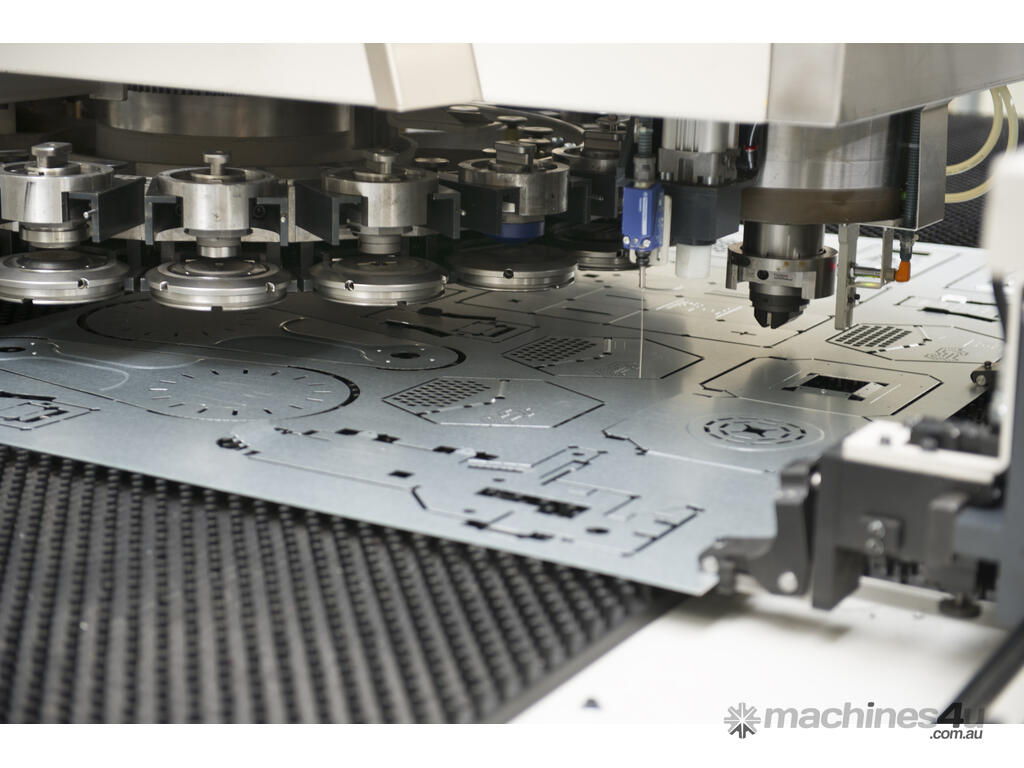

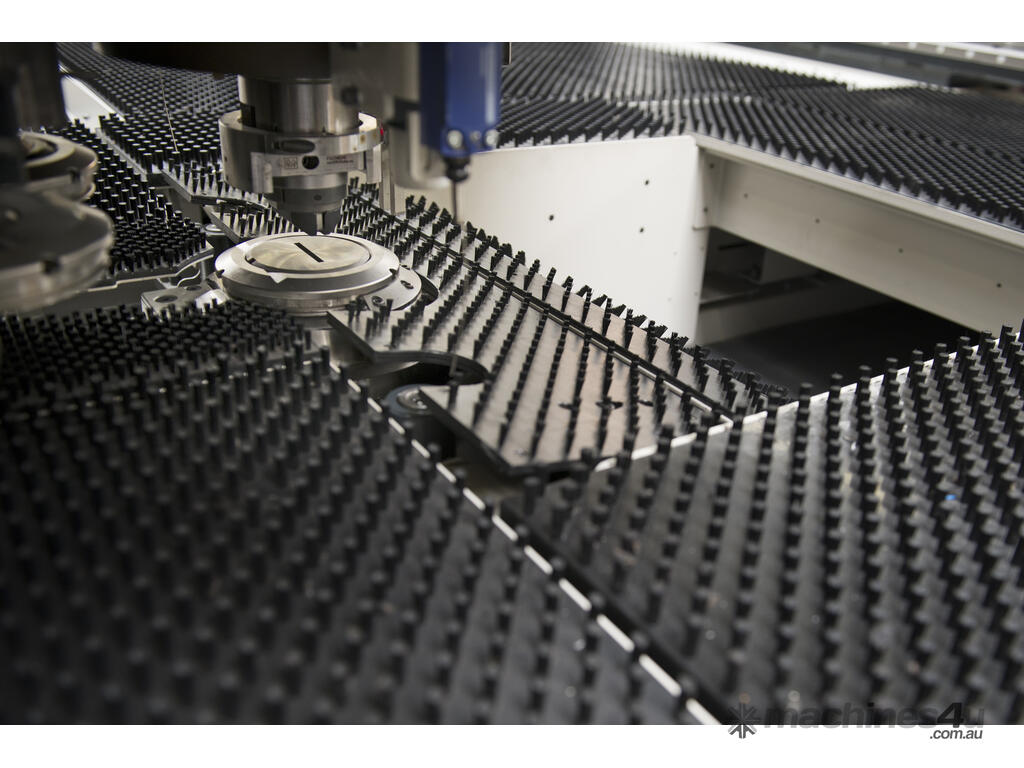

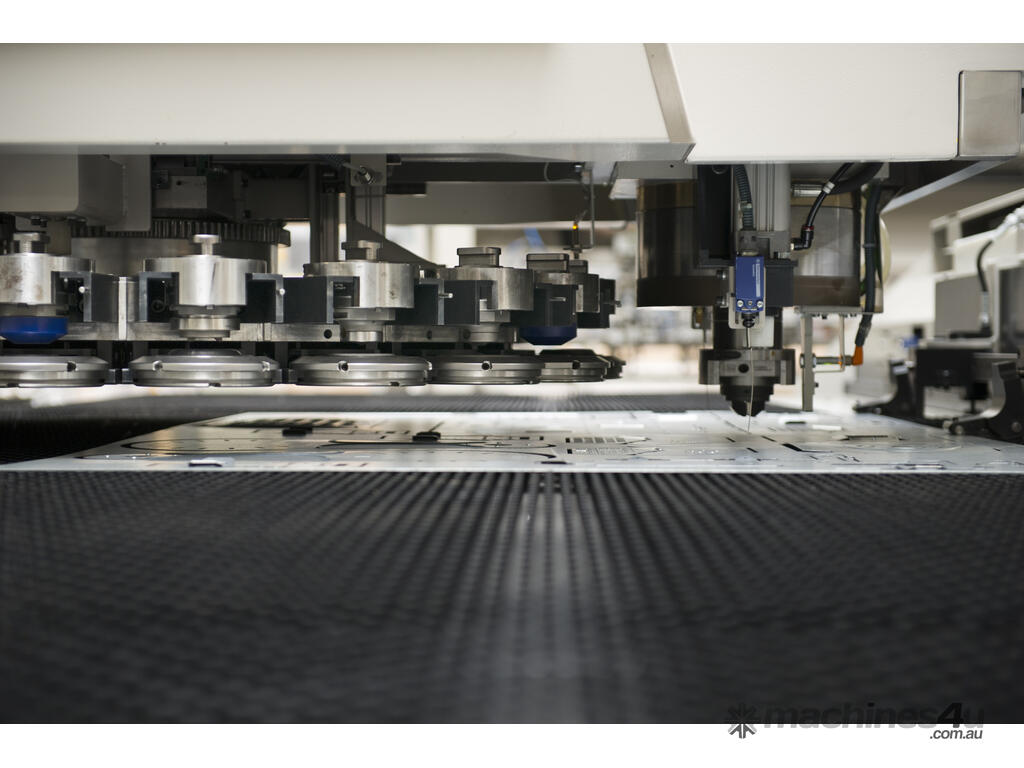

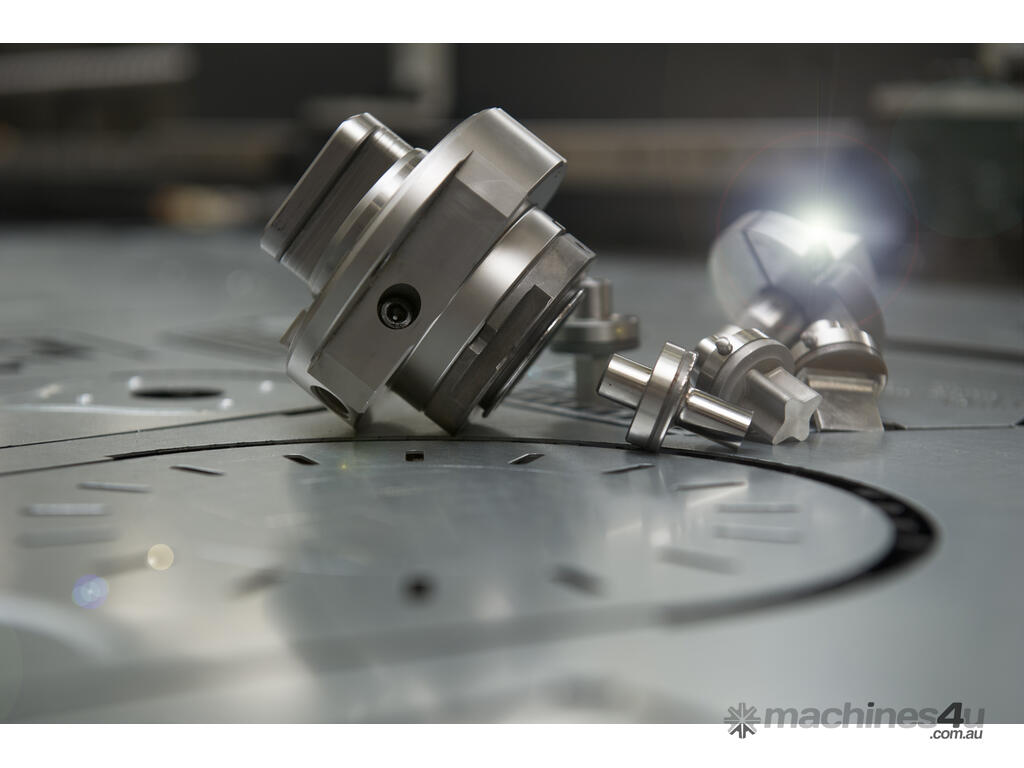

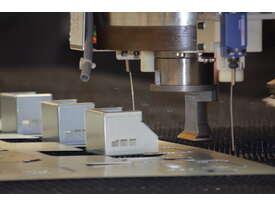

With 22 or 30 tons high speed servo hydraulic punching head, rotation axis for all tools, and standard interpolation parameters, the Haco series Q5 is the perfect and most flexible CNC turret punching machine. The large fully-brushed sheet support tables and the standard repositioning cylinders, allows standard sheet sizes to be processed easily.

The user friendly TPC69T Graphics controller offers everything you need to fit the high demands in contemporary punching. The high speed control, fast –processing and intuitive user interface results in an innovative system capable of handling simple as well as complex tasks. From the initial idea to the production of parts, the TPC69 graphics is your ideal partner.

Advantages of the Q5

- All tools are 360 ° auto indexable.

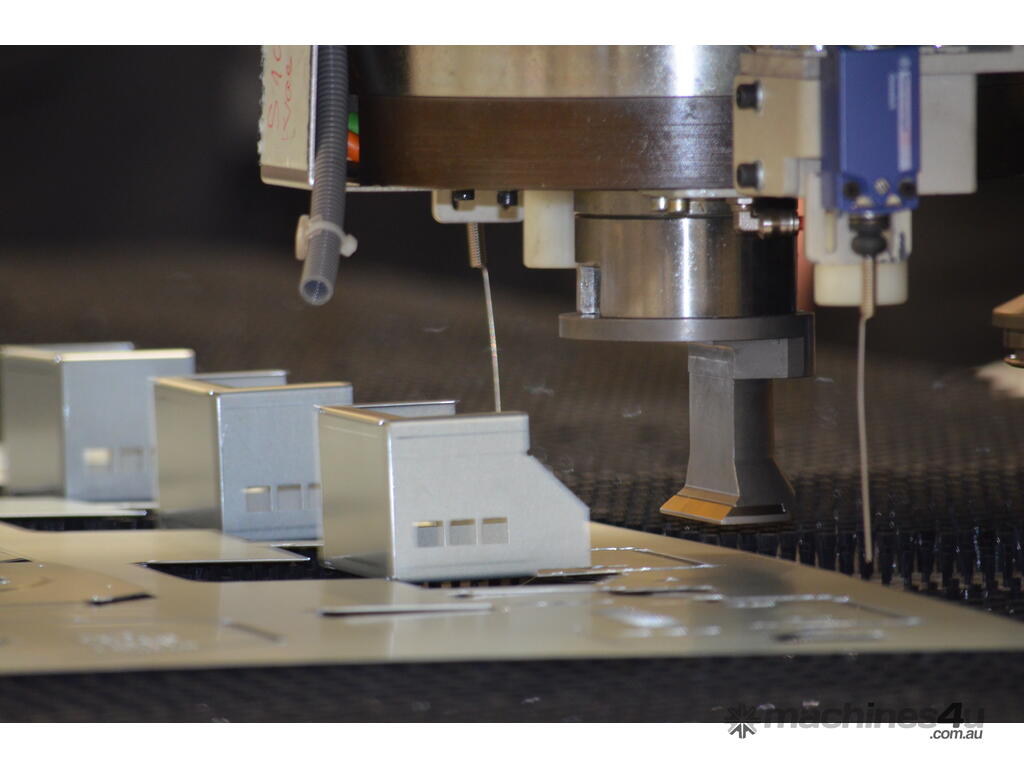

- Axis interpolation (use of wheel tools and ridged tapping is possible).

- Double Y axis for maximum speed and accuracy

- Automatic clamp setting by CNC = faster production times

- Big part chute door with protection system and integrated conveyor belt

- Energy saving via energy recovering from the motor drivers

- Easy and fast loading of tools into the turret

- Any tool station takes any tool (also Multi Tool)

- No complex turret composition = faster turret set-up

- No turret station wear, no turret adjustments

- Better adjustment for punch and die clearance than classic turret punching machines

- Positive tool clamping (no springs).

- Full control of stroke (Z-axis).

- Stripping plate has also hold down function.

- Urethane strippers can be used for scratch free production

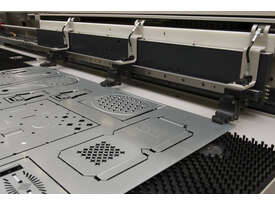

- Programs can be nested under every angle which results in optimal sheet usage and minimum rest sheet.

- No limitations in clamp setting

- Possibility of making large forming (Z axis stroke of 37 mm).

- Fast tool-change done by bidirectional rotation of the tool-turret that select automatically shortest rotation to the next tool.

- Standard slug suction device avoids the use of expensive ‘slug stop dies’.

Facebook

Facebook Twitter

Twitter

Email

Email

Print

Print